Blending & Dosing

Blenders

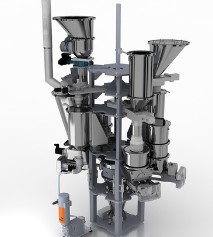

Maguire MaxiBatch™ - Blend Virtually any Combination of Power, Wood, Flour, Flake, Regrind, Pellet and Additive

Major advantages of the Maguire MaxiBatch™ Gravimetric Blender at a fraction of the cost and space required by previous methods:

- The world's largest throughput capacity up to 12,000 lb/hr (5500 kg/hr)

- Blends up to 12 ingredients

- Precise and efficient dosing of large quantities of bulk powders such as additives and wood flour

- Ability to easily add or remove dispense devices

- Bulk powder dispensing in a sealed environment

- High accuracy blending of a variety of ingredient types

- new 12-12 Controller with Twelve Component Software

- Option touch screen controller

The MaxiBatch™ blender accommodates twelve removable hoppers for as many ingredients, each hopper incorporates its own dispensing device designed for precise metering in large quantities.

As in other Maguire weigh blenders, ingredients are dispensed sequentially into a weigh chamber; the batch then falls into a mixing chamber. For more information on the MaxiBatch™ click here.

Maguire MicroBlender™ - The next generation in gravimetric blending

The WSB-MB MicroBlender™, the smallest weigh scale blender in the world, features the latest technology in gravimetric blending. The MicroBlender™ makes the benefits of gravimetric blending accessible and affordable to plastics processors operating small machines. The MicroBlender™ is capable of blending up to 4 components at a rate of 140 lb/hr (63 kg/hr). All material hoppers are removable for fast and convenient material changes. The Maguire Weigh Scale Blender controller is remotely mounted providing easy access for the operator.

Precise Dispensing System - Pneumatic valves operating in conjunction with advanced software deliver actual batch accuracy of (0.1%). The Maguire MicroBlender™ includes the unique Micro-Pulse technology, which virtually eliminates the need for augers to achieve accuracy when dispensing minor ingredients. Micro-Pulse gives you the capability of dispensing as few as 2 or 3 pellets per pulse cycle.

- Pneumatic valves operating in conjunction with advanced software deliver actual batch accuracy of (0.1%). The Maguire MicroBlender™ includes the unique Micro-Pulse technology, which virtually eliminates the need for augers to achieve accuracy when dispensing minor ingredients. Micro-Pulse gives you the capability of dispensing as few as 2 or 3 pellets per pulse cycle.

Reduced Weight and Footprint - Totally pneumatic system eliminates motors which reduces the weight of the blender to 50 lb. (22.7 kg). The unit is just under 2 feet high and has a 6 in. x 6 in. footprint.

Removable Material Supply Hoppers - Each of the removable bins contains a pneumatic quick disconnect for fast removal, cleaning, and replacement when changing colors of materials.

Unique Removable Access Door - The weigh pan and mix chamber are easily accessed through a removable door. The mix chamber agitator is permanently attached to the door and uncouples from the drive mechanism when the door is removed. This unique safety feature renders the agitator inoperable when the machine is opened and eliminates the need for electrical interlocks.

Vibration Management - Proprietary technology eliminates false load cell readings caused by machine shock or vibration. This greater accuracy is critical when the blender is mounted on a fast cycling molding machine.

Greater Documentation Capabilities - The MicroBlender™ can be linked with the Maguire materials management software for expanded control and reporting capabilities. Blend certification, process verification and documentation for ISO 9000 initiatives are among the requirements met by this data acquisition software. For more information on the WDB-MB MicroBlender click here.

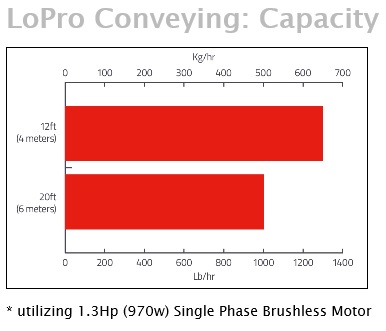

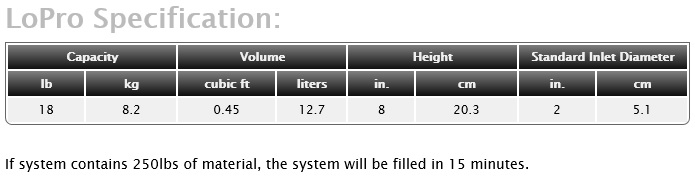

Maguire LoPro™

Low Profile Vacuum Loading System for Single & Multiple Blenders

Self-controlling receivers in Maguire's LoPro system are extremely compact at up to 80% reduction in height and easy to configure for automated 'mini-central' conveying to multiple blenders.

Features

- Low profile design

- Autonomous control

- Simple connection and installation

- Brushless motor

- Simple to operate

- Alarms

- Large discharge flap

- Simplified maintenance

- automatic filter cleaning

- 5-year warranty

- User-friendly side access

|

|

For more information on the LoPro click here.

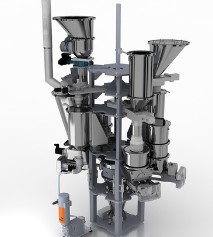

Dosing & Mixing Units

Perfectly blended, consistent quality. One of Motan's main strengths is knowing how to precisely dose and mix granulate, flakes, powders and liquids both volumetrically and gravimetrically. Proven consistent, high-quality results!

Volumetric

|

|

|

| MINIBLEND V | sCOLOR V | MINICOLOR SG V |

|

|

|

| MINICOLOR V | SPECTROFLEX V | SPECTROPLUS |

|

||

| SPECTROCOLOR V |

Gravimetric

|

|

|

| MINICOLOR G | GRAVICOLOR | SPECTROFLEX G |

|

||

| SPECTROPLUS |