HMI's / PLC's

ReeR Safety Controller Features

Safety controller is capable for monitoring several safety sensors such as safety light curtains, photocells, laser scanners, mechanical switches, mats, emergency stops, two-hand controls, concentrating management of these in a single, flexible device.

Advantages

- Reducing the number of devices and wiring used and, therefore, the overall

size of the project.

size of the project. - Allows tamper-proof system configurations.

- All logic is configured through a graphic interface. No more laborious wiring is needed as with traditional solutions.

- Speeding-up control panel construction.

- A lower number of electromechanical components also means a better Performance Level and, therefore, a higher Safety Level.

- The project report provides the actual values of PFH, DCavg and MTTFd according to EN 13849-1 and EN 62061

Main Features

- Mosaic is a safety hub able to manage all safety functions of a machinery or a plant.

- Modular & expandable.

- Configurable and scalable.

- Allows cost reductions and minimal wiring.

Leuze MSI400 Motion Safety PLC

Programmable Safety PLC of the Next Generation

The safety PLCs of the MSI 400 series provide efficient solutions for integrating safety sensors in machines and systems. Though just 45 mm wide, they are available with 24 safe inputs/outputs as well as an optional Ethernet interface with industrial Ethernet protocols. Additional extension modules and gateways adapt the control flexibly to current and future requirements. Configuration is simple and fast with the license-free programming software MSI.designer. A number of integrated comfort functions make work easier.

Advantages

- Simple integration in various fieldbus systems

- Modularly expandable to up to 116 safe inputs and 56 safe outputs

- 4A wear-free switching power at each output

- Simple handling of the projects through program memory in SD-card format

- Configuration made easy: with certified function modules, integrated simulation and logic analysis as well as a professional report function

- Special function blocks to control presses

Eurotherm - E+PLC100 Compact Precision PLC

The best in PID control and recording performance.

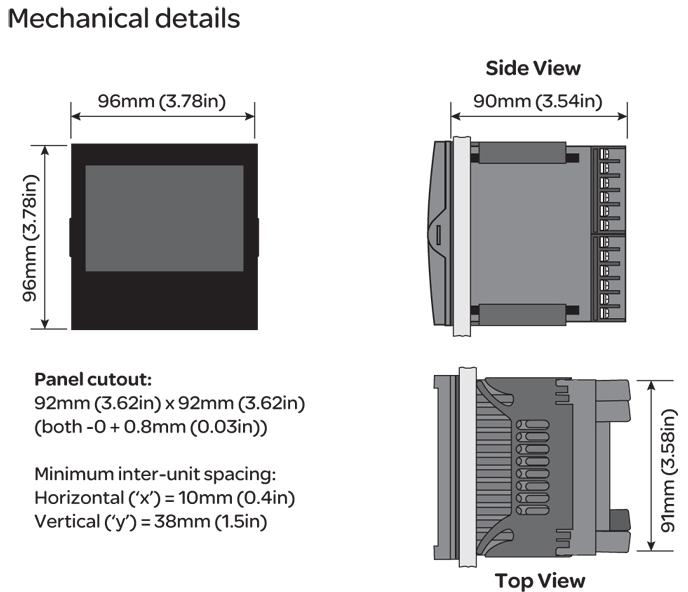

Eurotherm's E+PLC100 is a cleverly designed PID controller, recorder and PLC all in a compact, single box instrument with a 3.5" TFT colour touchscreen. Using an open industry standard (IEC 61131-3) platform and a single, integrated programming environment, it dramatically reduces engineering time while offering better process performance and easier regulatory compliance.

Eurotherm's E+PLC100 is a cleverly designed PID controller, recorder and PLC all in a compact, single box instrument with a 3.5" TFT colour touchscreen. Using an open industry standard (IEC 61131-3) platform and a single, integrated programming environment, it dramatically reduces engineering time while offering better process performance and easier regulatory compliance.

This exceptionally compact solution combines complete PLC functionality with the best in class PID control and recording. It offers a vivid operator interface which uses familiar touchscreen controls to ensure intuitive operation. For its size, it has an impressive selection of precision I/O and is an ideal complete solution for smaller applications.

- Open PLC with easy control and recording

- Single box solution

- Standard IEC 61131-3 programming

Single, integrated CodESyS programming environment offering PLC, PID control, recording and visualization - Pre-validated function blocks for rapid engineering

- Precision PID control in a PLC

- Accurate, stable control performance

- Reduces processing times

- Increases productivity

- Optimizes energy usage

- Improves quality

- Minimizes scrap/re-work

- Secure Recording in a PLC

- Easier regulatory compliance

- Precision measurement of process variables

- Secure data recording at point of measurement

- Complete, accurate, traceable records

- A PLC with Integrated visualization

- Intuitive, integrated touchscreen display

- Mobile process viewing on PCs, tablets and smartphones

| Features: | |

| Archiving Strategy | - Yes |

| Autotuning PID | - Yes |

| Available I/O | - (Dependent on build variant) AI(4), AO(3), DI(2), RLY(3) |

| Batch Management | - Yes |

| Communications Protocols | - FTP Modbus TCP/IP (Master/Slave) |

| I/O Expansion Method | - Modbus |

| Mounting | - Panel |

| Panel HMI (Protocol) | - Built-in (OPC DA) |

| Product I/O Format | - Fixed |

| Programming Languages | IEC61131-3 compliant CFC, FBD, IL, LD, SFC, ST |

| Programming Platform | - CODESYS (open) |

| Recording Duration (approx.) | - Based on 4 chs at intervals of: 1s 12.97days, 10s 129.7 days, 20s 259 days, 60s 2.13 years |

| Secure Recording | - Yes |

| Setpoint Programmer | - Yes |

| Suitable for AMS2750E Process | - Yes |

| Web Visualization | - Yes |

Delta - Touch Panel HMI - Human Machine Interfaces

A human machine interface (HMI) is a platform which permits interaction between  users and automation equipment. Delta’s HMI products provide various communication ports for fast communication and convenient control of a diverse range of machines, systems and facilities. The color touchscreen enables intuitive parameter entry and a variety of ways to display variable data, including trend graphs and alarm elements. The high resolution LCD display visualizes operating, monitoring and efficient control in real time. In addition, the user-friendly editing software guides users in quickly creating easy-to-navigate visual icons and easily designing intuitive monitoring screens for applications, while making adjustments, scheduling, and programming operational sequences that enhance flexibility and save development time. This achieves rapid system development that simplifies wiring and installation, saves operating expenses, and makes systems more efficient, eliminating time-consuming adjustment and additional maintenance costs.

users and automation equipment. Delta’s HMI products provide various communication ports for fast communication and convenient control of a diverse range of machines, systems and facilities. The color touchscreen enables intuitive parameter entry and a variety of ways to display variable data, including trend graphs and alarm elements. The high resolution LCD display visualizes operating, monitoring and efficient control in real time. In addition, the user-friendly editing software guides users in quickly creating easy-to-navigate visual icons and easily designing intuitive monitoring screens for applications, while making adjustments, scheduling, and programming operational sequences that enhance flexibility and save development time. This achieves rapid system development that simplifies wiring and installation, saves operating expenses, and makes systems more efficient, eliminating time-consuming adjustment and additional maintenance costs.

Product Series List

DOP-100 Series - Delta’s Human Machine Interface DOP-100 Series adopts the latest Cortex-A8 high speed processor and 65,536 color LCD display panel with high brightness and contrast. The DOP-100 Series supports multiple network functions, including FTP, E-Mail, VNC (Virtual Network Computing) Remote Monitoring, and NTP (Network Time Protocols) to meet customer requirements for cloud applications and smart manufacturing.

latest Cortex-A8 high speed processor and 65,536 color LCD display panel with high brightness and contrast. The DOP-100 Series supports multiple network functions, including FTP, E-Mail, VNC (Virtual Network Computing) Remote Monitoring, and NTP (Network Time Protocols) to meet customer requirements for cloud applications and smart manufacturing.

- Advanced HMI - The Advanced HMI adopts a narrow frame and wide screen design. It is equipped with more than one COM port and an Ethernet port. Featuring a multilingual input function, it provides easy operation for global customers.

- Standard HMI - The Standard HMI is equipped with 2+ COM ports to meet most customer requirements. The Standard Ethernet Type offers and Ethernet port for fast connection with other equipment.

- Basic HMI - The Basic HMI features basic functions and easy installation for industrial applications. With IP55 waterproof protection, it is suitable for harsh environments.

DOP-W Series - The DOP-W Series is a large Human Machine Interface (HMI) that comes with a high resolution and high brightness touch screen in 10.4”, 12” and 15” sizes. With the latest Cortex-A8 processor for up to 1GHz pulse wave, the DOP-W Series delivers high performance with rapid response. Its rugged and CE-certified aluminum enclosure protects from vibration and changing ambient temperatures, and features an IP65 waterproof front panel for harsh environments. Built-in stereo speakers increase utility and flexibility. The DOP-W Series complies with CE and UL safety approvals and provides an efficient and competitive solution to meet customer needs for a wide range of high-end industrial automation applications.

DOP-H Series - Delta's DOP-H series handheld type HMIs feature a 7-inch high resolution LCD  display for visualizing operating, monitoring and efficient control in real time. All series are equipped with built-in emergency stop switches, rear side enable switches, optional MPG (Manual Pulse Generator) and lightweight 750g design for higher flexibility and user-friendly operation. The DOP-H series is suitable for controlling industrial robots and programming the motion of robot arms and other motion control systems.

display for visualizing operating, monitoring and efficient control in real time. All series are equipped with built-in emergency stop switches, rear side enable switches, optional MPG (Manual Pulse Generator) and lightweight 750g design for higher flexibility and user-friendly operation. The DOP-H series is suitable for controlling industrial robots and programming the motion of robot arms and other motion control systems.

HMC Series - The HMC Series is a new and advanced human machine interface which has additional built-in PLC functions for sequence control. To make high precision control and high level performance possible, the HMC Series is equipped with two high-speed CPUs which ensure the execution efficiency and the performance of the system when running large and complicated PLC programs. Using Delta's DMCNET high speed and real time communication bus, the HMC Series is capable of connecting to the ASDA Series servo drives to provide high-performance synchronous motion control to meet the demanding requirements of high speed movement and high precision positioning.

TP Series - The TP70P Series adopts a 65535 colors LCD touchscreen, supports  Delta’s controllers, and can be connected to all series of Delta’s AC servo drives, AC motor drives, and temperature controllers. With four models providing different I/O configurations and supporting various output types, TP70P Series high flexibility saves wiring costs and offers the best HHMI and I/O control solution.

Delta’s controllers, and can be connected to all series of Delta’s AC servo drives, AC motor drives, and temperature controllers. With four models providing different I/O configurations and supporting various output types, TP70P Series high flexibility saves wiring costs and offers the best HHMI and I/O control solution.