Materials Handling & Drying

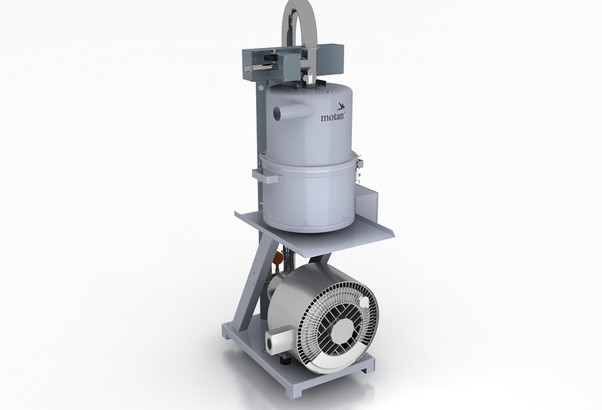

Motan's New Swift sCOMPACT 80/150/250

Compact Dryer with Integrated Conveying - Swift simple units, combined with state-of-the-art control technology.

The new Swift product family comprises the most cost-efficient models of the Motan product portfolio. Swift products are quick and easy to operate. Whether for standardized injection molding, blow molding, or extrusion applications – they are always the right choice. The Swift product family not only represents value for money, quick delivery and the usual Motan quality, but also state-of-the-art control technology.

product portfolio. Swift products are quick and easy to operate. Whether for standardized injection molding, blow molding, or extrusion applications – they are always the right choice. The Swift product family not only represents value for money, quick delivery and the usual Motan quality, but also state-of-the-art control technology.

The sCOMPACT S and sCOMPACT A dryers are designed for sCOMPACT 80/150/250 flexible material processing in the production line and are suitable for use with a processing machine. They offer a system-specific solution with integrated conveying and a drying bin. The dryers are available in three versions and are each equipped with one drying bin of the size 80, 150 or 250 liters and a hopper loader with a capacity of 4 liters. The sCOMPACT A dryer is provided with advanced functions such as the dew point control and the dry air conveying function with purging. The sCOMPACT 250 dryer can optionally supply two processing machines.

The sCOMPACT dryers are developed especially in order to guarantee a stable drying process. The two desiccant cartridges generate a continuous dry air flow with low dew point and are perfectly suitable for production facilities with high air temperatures and high ambient humidity.

Features

|

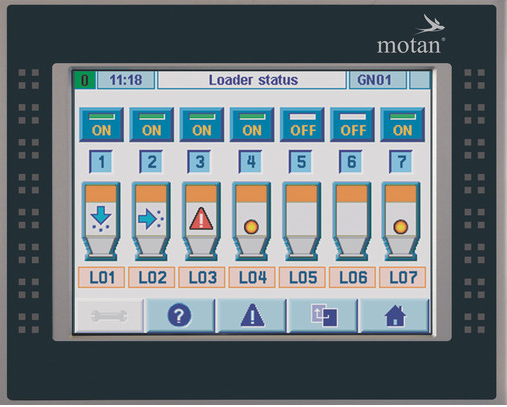

Simple and easy to operate with state-of-the-art control technology. Simplest handling by a modern microprocessor control. Thanks to a modern 7" touch screen color display, all conveying and drying functions can be shown and monitored in a user-friendly way. 16 user languages can easily be selected. 128 MB RAM, 128 MB Flash. Dew point control. |

|

The integrated conveying function in the sCOMPACT saves you space and money as no separate conveying system is needed. It can control up to one drying bin hopper loader and one machine loader, as well as the blower and filter. |

|

All drying models are equipped with especially large cleaning doors with an inspection window and can be opened with the help of a quick-release lock. The doors are adapted to the shape of the drying bin which optimizes the material flow and makes cleaning easier. A hinged lid facilitates the access from above. |

|

A three-phase side channel blower is used for conveying. They are maintenance-free and have a long service life. Thanks to the low-noise, simple and compact design, the blowers can be installed directly in the dry air generator. IE3 motors for all blowers with 0,85KW and larger. |

|

Fully insulated drying bin - The entire drying bin including material discharge is completely heat-insulated. This ensures stable conditions in the bin and saves energy. |

|

Each dryer is equipped with two fully insulated, stationary desiccant beds. On the one hand, this saves the user energy in the drying process and ensures constant drying air quality thanks to the large molecular sieve cartridges. On the other hand, the dryers are very reliable due to the long drying cycles, infrequent regeneration, and no moving parts. |

| View Motans Swift sCompact 80/150/250 Brochure |

For more information on the sCOMPACT Dryer Series by Motan, give your local Barry Sales Representive a call at 636.326.1211.

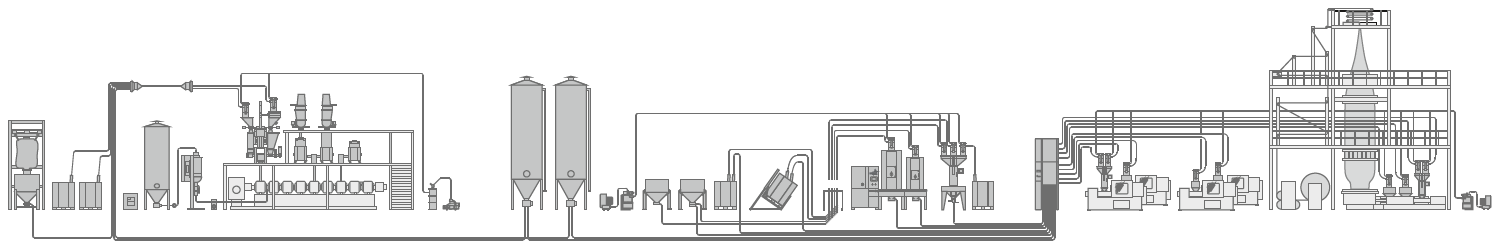

Central Conveying of Pellets and Powders

Motan is a world leading supplier of complex centralized material feed systems. Each system is designed to suit the customers individual factors such as throughput, materials types, and plant layout. A wide selection of loaders with a variety of conveying options, controls, blowers, and filter techniques allow the creation of the optimum system for the customers facility.

System Controls - From simple cost effective solutions to innovative state-of-the-art controls with Ethernet-based open network architecture. There are several different levels of automation are available for controlling the METRO G loaders.

SELVAC 2 - market-proven microprocessor-based  control.

control.

METROnet S - a soft PLC conveying control for standard conveying systems.

METROnet AE and AN - the ultimate networkable system toolkit for complex conveying systems with either a soft PLC or Siemens S7 PLC with WEBpanel and decentralized CAN Bus nodes for the connection of peripheral equipment.

All METROnet controls are totally integrated in the CONTROLnet platform and can be linked to other controls via Ethernet

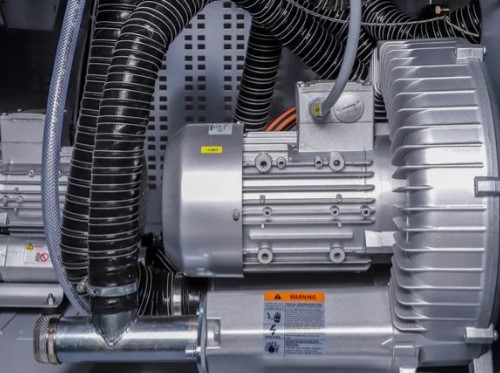

Positive Displacement Vacuum Pumps - High  efficiency, claw style positive displacement pumps provide the highest level of vacuum power available for conveying plastic material. The variable frequency pumps employ an advanced claw-shaped lobe design that cuts through and pressurizes air in a nearly maintenance free package. These pumps deliver stronger conveying performance at longer distances and higher elevations for challenging conveying applications.

efficiency, claw style positive displacement pumps provide the highest level of vacuum power available for conveying plastic material. The variable frequency pumps employ an advanced claw-shaped lobe design that cuts through and pressurizes air in a nearly maintenance free package. These pumps deliver stronger conveying performance at longer distances and higher elevations for challenging conveying applications.

Automatic Conveying Equates to Greater Productivity

Motan's conveying systems optimize material flow, reduce waste and boost the productivity of the production line. Motan offers integrated, end-to-end conveying systems and individual units. (click on the images below to see more information).

|

|

|

|

| Metro HES/MeS | Metro HBS | Metro G | Central Conveying |

|

|

|

|

| Metroconnect | Metrolink | Metal Separator | Metro P |

Motan Luxor Drying Systems

Lower costs, higher-quality drying. Motan Colortronic drying systems are designed to be energy efficient. Patented ETA plus® technology helps you reduce energy consumption by up to 64 percent, and, thanks to the Drying Organizer, you can be sure of excellent results each time.

|

|

|

| Luxor HD - Hot Air | Luxor CA S - Dry Air | Luxor CA - Dry Air |

|

|

|

| Luxor S - Dry Air | Luxor EM A - Dry Air | Luxor A - Dry Air |

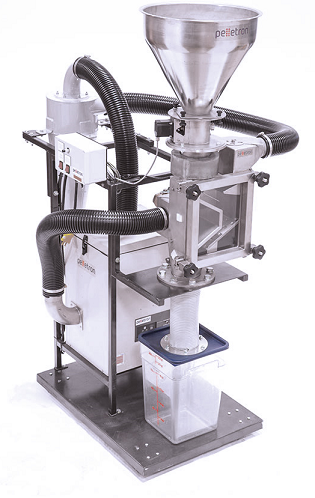

Pelletron DeDuster

Pelletron DeDuster was developed as a result of demands for high quality standards in the plastics industry, but the technology can be used for all kinds of granular bulk materials. The list of requirements for a new, universal dedusting machine was long:

- Remove dust and streamers with one machine

- Separate and remove electro-statically charged dust particles

- Fit on injection molding machines

- Offer low construction height

- Fit on top of extruders and under silos

- Reduce remaining dust level after cleaning to <50PPM

To address this list of requirements, Pelletron developed a cleaning machine that combines a variety of air wash principles, plus the revolutionary electro-static flux field feature, and built it with the lowest possible construction height. When electrostatically charged particles enter into the Magnetic Flux Field, the resulting “Lorentz Force” weakens the electro-static bond between fine dust and plastic pellets. This weakening, in combination with the air flow, allows the micro fine particles attracted to the pellet surfaces to be removed.

To address this list of requirements, Pelletron developed a cleaning machine that combines a variety of air wash principles, plus the revolutionary electro-static flux field feature, and built it with the lowest possible construction height. When electrostatically charged particles enter into the Magnetic Flux Field, the resulting “Lorentz Force” weakens the electro-static bond between fine dust and plastic pellets. This weakening, in combination with the air flow, allows the micro fine particles attracted to the pellet surfaces to be removed.

To learn more about the various DeDuster models available please contact your local Barry Sales Engineering representative.

Industrial Material Handling Equipment

Ensign is a one-stop-source, providing a range of products and services from integrated bulk handling system to parts and accessories. Filling, weighting, conveying, unloading, mixing, dumping, storing, and more. Choose from a broad spectrum of reliable, high performance equipment in carbon steel, stainless or aluminum to meet or exceed the rigorous standards of your application.

Ensign designs equipment and systems that can meet  your specified process requirements. Various applications include films, flakes, pellets, chips, fibers, granules, powders and dissimilar materials of various types, densities, sizes and characteristics.

your specified process requirements. Various applications include films, flakes, pellets, chips, fibers, granules, powders and dissimilar materials of various types, densities, sizes and characteristics.

Equipment Range includes:

|

|

Looking For Labor-Free Gaylord Unloading? Consider it Handled?

Ensign’s tote tippers are an economical and nearly labor-free method for unloading gaylords, bins, boxes, drums, and various other containers. Capable of automatically or manually tilting when the container is approximately half empty, Ensign’s Tote Tipper can lift up to 1,000lbs at 80 psi to a 45-degree angle ensuring all material is evacuated from the container. The ground entry tilting pan can be loaded from the floor with a pallet jack, forklift, or hand truck. The tilting pan pivots on two serviceable and replaceable flanged bearings. Unlike other products on the market, the bearings on this tote tipper require very little maintenance and ensure smooth rotation during the entire tilt cycle even years after installation.

gaylords, bins, boxes, drums, and various other containers. Capable of automatically or manually tilting when the container is approximately half empty, Ensign’s Tote Tipper can lift up to 1,000lbs at 80 psi to a 45-degree angle ensuring all material is evacuated from the container. The ground entry tilting pan can be loaded from the floor with a pallet jack, forklift, or hand truck. The tilting pan pivots on two serviceable and replaceable flanged bearings. Unlike other products on the market, the bearings on this tote tipper require very little maintenance and ensure smooth rotation during the entire tilt cycle even years after installation.

Features

- Firestone Air bag

- Ground Entry

- Serviceable/Replaceable Pivot Bearings

- Stainless Steel Construction

- Custom Colors

- Vacuum Wand Holder

- Gaylord retaining hook

- Full Tilt Indicator

- Safety Ratchet Assembly

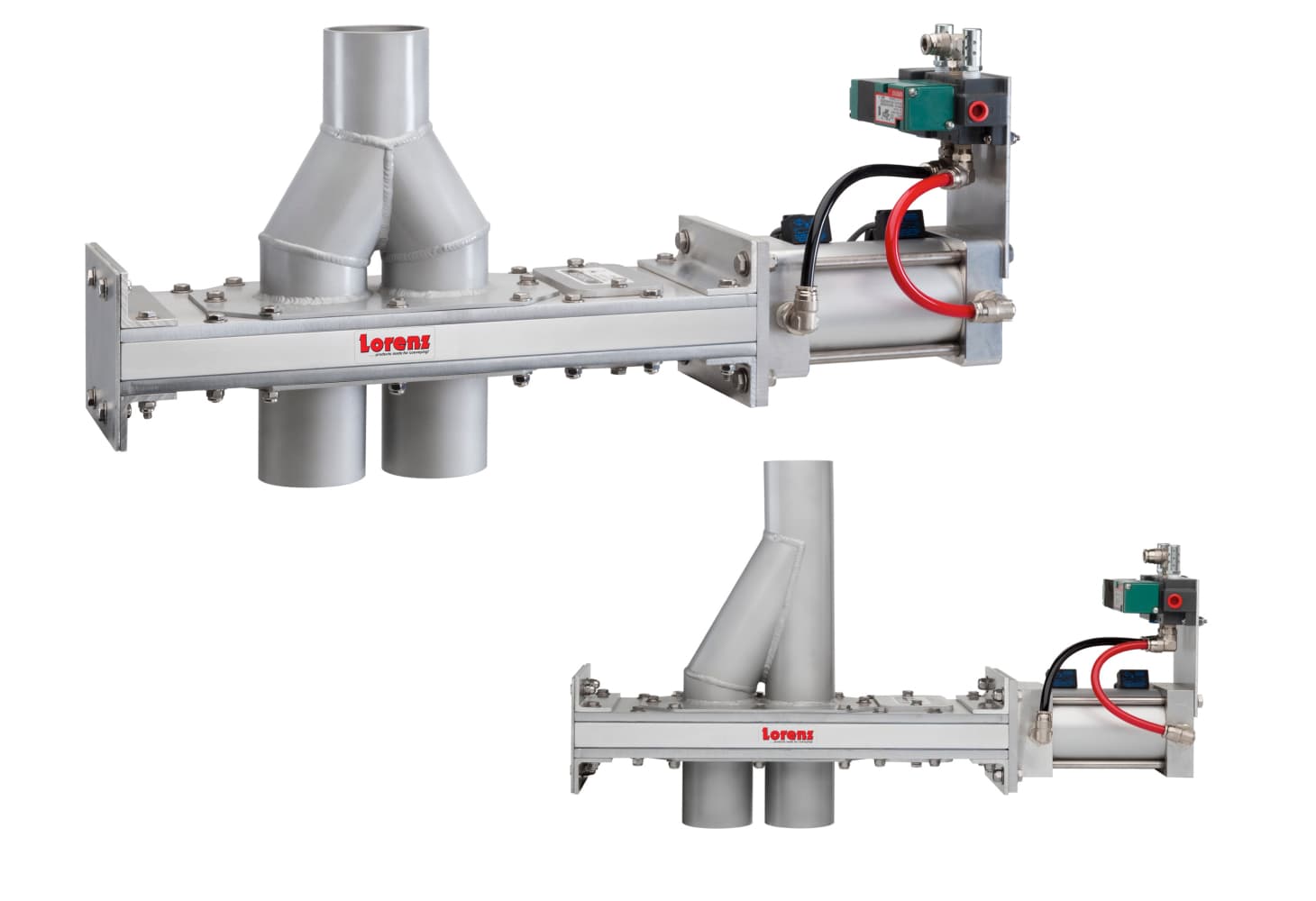

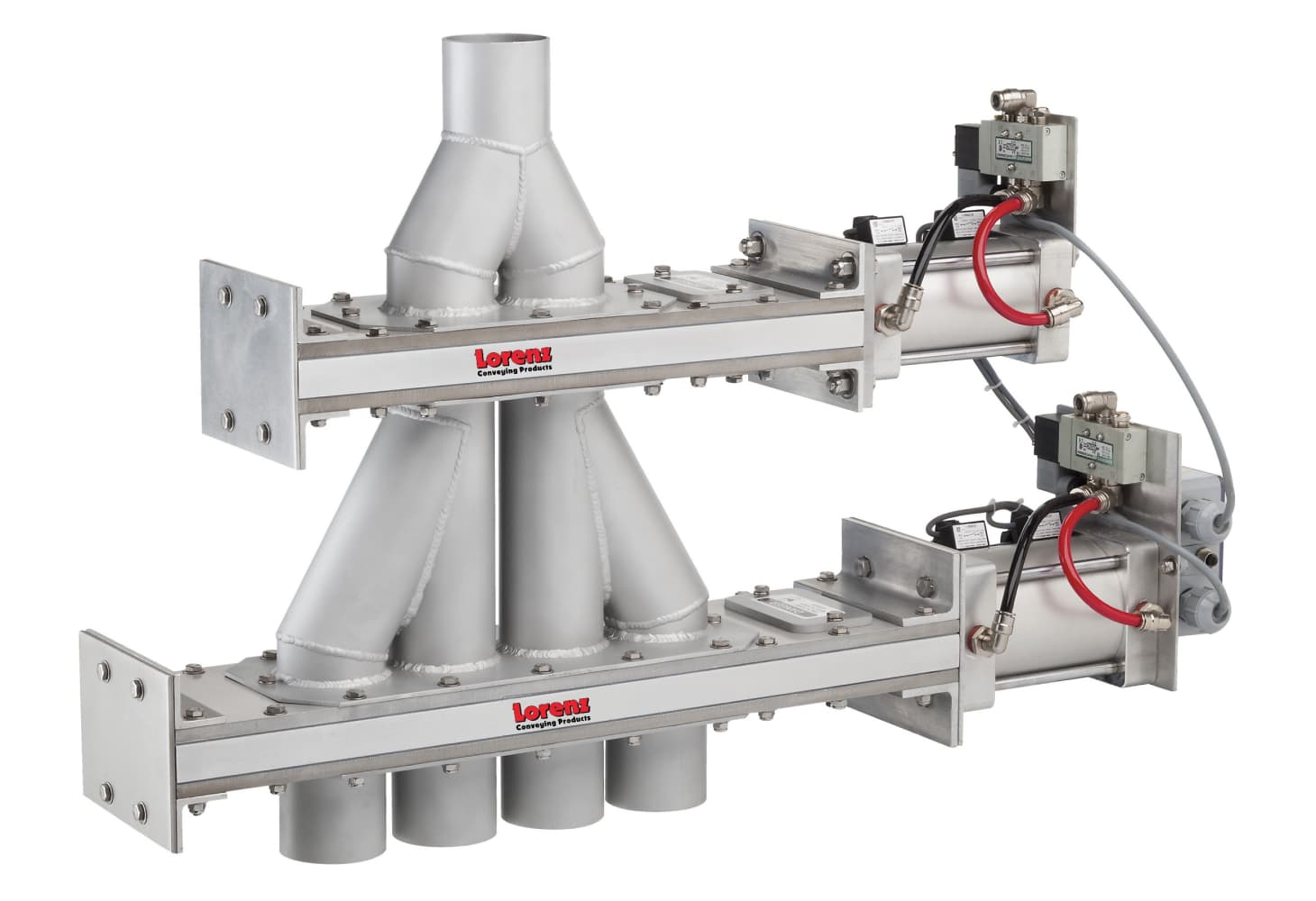

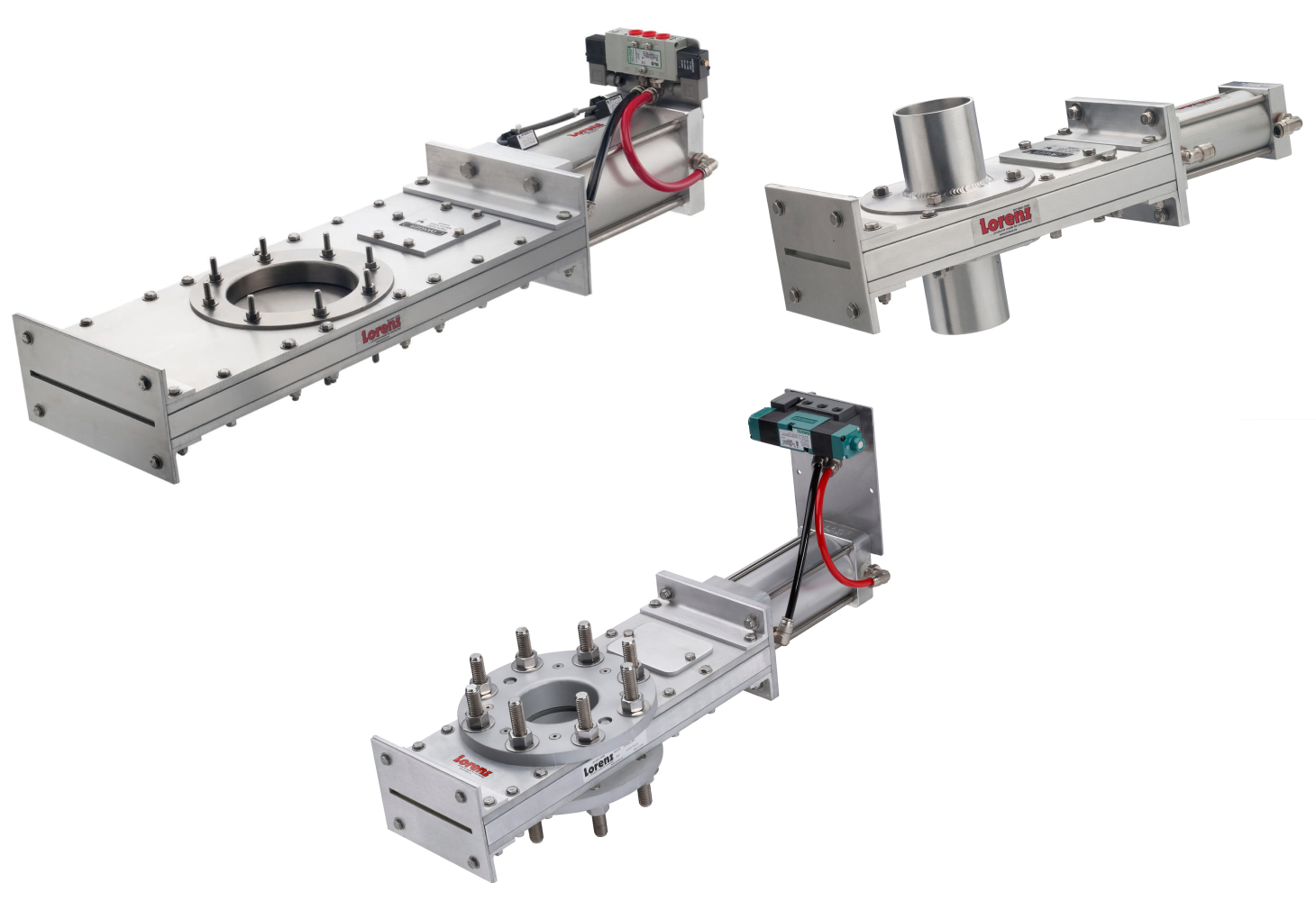

Lorenz Conveying Products is a leading manufacturer of diverter valves, slide gates, as well as custom fabricated accessories for pneumatic conveying, vacuum and bulk handling systems.

Angel Hair Traps - Collect “Angel Hair”, “Streamers” or “Snake Skins” common in the conveying of plastic materials at the base of a silo or storage bin in gravity applications.

applications.

Standard Features

- Aluminum construction

- Low profile design is only 8.5” high

- Easy clean/removable screens available in Stainless Steel or Aluminum 3/4” expanded metal size (1/2” expanded metal optional)

- Standard unit mounts directly to 12” square bolt hole pattern Lorenz Maintenance Gates and Distribution (Probe) Boxes

- Optional 6” height available

- Custom sizes available

In-Line Angel Hair Traps - Designed to mount in the material stream to collect “angel hair”, “streamers” or “snake skins” while allowing the pellets to pass through.

“angel hair”, “streamers” or “snake skins” while allowing the pellets to pass through.

Standard Features

- Eliminate downtime caused by Angel Hair and Streamers

- The clear viewing cover for level indication can be quickly removed for clean out

- For use in vacuum lines and pressure conveying systems

- Three standard body sizes are 8”-10” and 18” with line sizes from 1.5” OD up to 6” OD

- Body constructed of 12 gauge 304 Stainless Steel

- Connects to line with compression couplings

- Black knobs standard

Diverter Valves - Available in 1.5” – 12” OD pipe sizing- allows for diverting plastic pellets from one to several other locations- one at a time with no cross contamination.

2, 3 & 4 Way Diverter Valves / Series D are used for Vacuum or Diluted Phase Pressure Applications (for more information select the image below).

| 2 Way Diverter Valves | 3 Way Diverter Valves | 4 Way Diverter Valves |

|

|

|

Slide Gates - Manual, pneumatically and automatically actuated slide gates for Silos, surge bins and storage hoppers. (for more information select the image below).

| Slide Gate / Series E Shutoff dry bulk conveying lines under vacuum, pressure (dilute phase 15 psi mx) or gravity. |

Roller Gate / Series N Used in high cycle gravity flow applications. |

|

|

Compressed Air & Desiccant Drying Technology - Easy to use Dryers

Dri-Air Industries is the leader in compressed air and desiccant drying technology. Their line of plastics drying and loading systems offer a full-range of solutions for drying plastic resins, mixing, blending and conveying virgin, regrind and plastic colorants. Dri-Air offers a proven patented 4 bed desiccant dryer design for faster drying plastic pellets with no moving parts. These desiccant drying systems also include advanced microprocessor controls, stainless steel insulated drying hoppers.

Their line of plastics drying and loading systems offer a full-range of solutions for drying plastic resins, mixing, blending and conveying virgin, regrind and plastic colorants. Dri-Air offers a proven patented 4 bed desiccant dryer design for faster drying plastic pellets with no moving parts. These desiccant drying systems also include advanced microprocessor controls, stainless steel insulated drying hoppers.

Arid-X Mini Dryer

Ideal for lab, insert and small molding machines up to 10 pounds per hour, the industries smallest two bed dryer!

No Compressed Air Required!

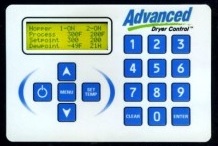

- Now available with ADC dryer control which includes -49F dewpoint monitor, 7 day timer and diagnostic functions

- ELC control is standard with high temperature alarm and shut down

- Space saving design 11"W x 18"D x 21" H

Compressed Air Mini Dryer

The compressed air dryers are compact, easy to use dryers that uses your plant air and internal Dri-Pak membrane to assure -49F dewpoint air to the drying hopper.

- For throughputs up to 10 pounds per hour

- Ideal for low 80 F and high temperature 350 F applications without cooling water

- Available with our ADC dryer control which includes: -49 F dewpoint monitor, 7 day timer and diagnostic functions

- ELC control is standard with high temperature alarm and shut down

- Space saving design 11″ w x 18″ d x 21″ high

| View Brochure |

Vacuum Drying: A Revolution in Dryers

Maguire Vacuum dryers are proven to dry plastics materials 6 times faster than conventional dryers and use up to 85% less energy. The reduced drying time required with the vacuum dryer dramatically reduces the risk of material degradation. There are 3 x VBD models to choose from and 3 x LPD models to choose from, catering for both small and large lb/hr (kg/hr) throughputs.

|

|

|

| LPD 30 | LPD 100 | LPD 200 |

|

|

|

| VBD-150 | VBD-300 | VBD-1000 |

| View Brochure |

Components & Material Handling Accessories

Our pneumatic conveying product line supplies tubing, piping, couplings, fittings, specialty material handling hose and accessories for the air transfer of dry powder, plastic pellets and bulk materials.

Our HP line offers tubing from 1.5" OD to 10" OD and pipe from 1" NPS to 8" NPS and tube bending capabilities range from 1.75" to 72" center line radius and our pipe bending capabilities range from 5" to 72" center line radius. We offer a variety of necessary couplings, fittings, and accessories to complement our tubing. Please give your local Barry Sales Representative a call if you would like to place an order or have any questions.

Resin Bins

Storage & Transfer of Material

MAC Resin Bins can be customized in many ways. Vacuum components can be added to the top or bottom, you can add convenient lid holders to the side, as well as other soft good accessories are available.

MAC Resin Bins can be customized in many ways. Vacuum components can be added to the top or bottom, you can add convenient lid holders to the side, as well as other soft good accessories are available.

Self-emptying resin bins are designed for use with vacuum loading systems using pickup wands. The vacuum wand is inserted into a tube on the bin. This tube is angled and directed to the lowest point in the bin where resin can be picked up by the wand. Unit comes with a lid, full swivel casters, and most are stackable up to three high! EXCLUDING Models: RB800C & RB1200C.

Using resin bins in a plastic injection molding plant can immediately help with material control and cleanliness. Resin bins are a perfect solution to health and safety regulations controlling the manual lifting of heavy loads such as bags of raw material.