Blow Molding

Dri-Air Floor Mount Dryers

Model 50-100 and Model 150, 200 & 300

No Moving or Rotating Internal Parts

- Space-saving compact design available for process rates up to 750 lbs/hr.

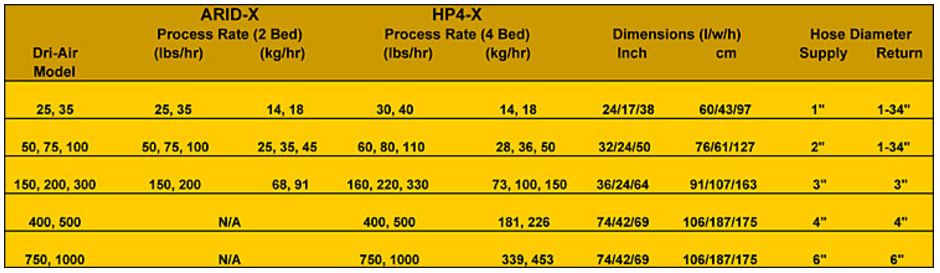

- Models are available in industry-standard 2-bed (ARIX-X-FM Series) and high-performance 4-bed (HP4-X FM Series)

- Combine with a press/extruder mounted drying hopper for a complete system

- Dryer hoses and casters are included

Energy Efficiency

- Most energy efficient dryer in the market (when compared to compressed air, rotary wheel, vacuum and other dual bed dryers)

- Single blower design for process and regeneration air

- On-demand regeneration; adjusts to ambient conditions, materials and process rates

- Desiccant tower design maximizes heat transfer

- -49ºF to -130ºF dew points; as dry air; not ambient air is used for regeneration or cool down of desiccant towers, slip stream of low dew point air is used

- Can be used with Hopper Bank Series and multi-hopper systems

- ADC Control is standard and includes:

- -49ºF dewpoint monitor

- 7 day timer

- Diagnostic functions

- Dewpoint, heater, and temperature alarm

Optional Items Include

- Water after-cooler, plasticizer trap and high temperature hose

- Visual and audible alarms available

- Temperature setback reduces drying temperature when material is dry to prevent overdrying

- Dri-Touch, 7" touch screen on HP4-X models

Motan Metro G Loader

Comprehensive and Flexible

Metro G for Granules

METRO G is the most comprehensive and flexible material loader range on the market. It  combines the best of two established material loader ranges – Colortronic and Motan. Whether simple of highly complex, METRO G’s modular building block system will provide you with an individual solution tailored to your demands.

combines the best of two established material loader ranges – Colortronic and Motan. Whether simple of highly complex, METRO G’s modular building block system will provide you with an individual solution tailored to your demands.

Module Design

No product redundancy - as your production requirements change so does the material loader. All material loaders are fully modular and can be matched to different throughputs and requirements depending on the application. Not only are there different material loader volumes, but also different material inlet and outlet sizes which can be accurately adapted to suit throughputs and conveying distances. The option of either a glass or steel hopper body is available for most loaders.

Perfect for conveying hygroscopic materials with small throughputs, or where space is limited, a machine loader version is available. The discharge module of the loader has no discharge flap and the unit must be mounted directly on the feed throat of the processing machine.

The benefit to you is that no machine supply hopper is required and very little material stays at the machine. This is especially important for dried materials as the residence time of the material is kept to an absolute minimum.