Injection Molding

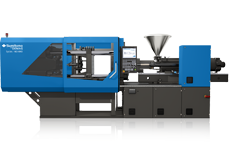

Double-Shot SE-HS-CI Series All-Electric Injection Molding

Models: SE230HS-CI, SE280HS-CI, and SE400HS-CI

Sumitomo (SHI) Demag’s double-shot SE-HS-CI Series of all-electric injection molding machines sets a new standard for high-profitability multi-shot/multi-material molding with high speeds and exceptional precision, energy efficiency, versatility and ease of use. It combines Sumitomo’s advanced all-electric motor technology found on the high-speed SE-HSZ Series with two injection units and a high-speed, high-accuracy rotating plate.

injection molding machines sets a new standard for high-profitability multi-shot/multi-material molding with high speeds and exceptional precision, energy efficiency, versatility and ease of use. It combines Sumitomo’s advanced all-electric motor technology found on the high-speed SE-HSZ Series with two injection units and a high-speed, high-accuracy rotating plate.

The SE-HS-CI is offered in three model sizes: the SE230HS-CI (253 U.S. tons), SE280HS-CI (308 U.S. tons), and SE400HS-CI (440 U.S. tons). Designed with flexibility for a wide range of double-shot applications, the SE-HS-CI:

- Has a wide mold space that accommodates existing single-shot molds or integrated double-shot molds

- Is available with a choice of injection units, screw diameters and screw types for shot sizes ranging from 2.9 to 10.7 ounces

- Delivers high injection speeds (300 mm/sec) and high pressures (up to 41,248 psi)

Other features of the high-speed SE-HS-CI all-electric injection molding machines include:

- 180° mold plate rotation in 0.8 seconds (compared with a typical 2.0 seconds, this achieves a 1.2 second reduction in cycle time)

- Faster mold open and close speeds of 1300 mm/sec (51.2 in./sec)

- Easy-to-use, PC-based N-9 controller with full SPC and QC capabilities

- Double Center Press Platen (DCPP) design that ensures superior surface pressure balance throughout the central surface area of the double-shot mold(s)

- A patent-pending, closed-loop clamp-force correcting system that uses a tie-bar mounted clamp-force sensor

The SE-HS-CI is backed by a comprehensive Customer Satisfaction Program with Sumitomo (SHI) Demag’s standard-setting warranty program, worry-free parts, responsive field service, and financing availability — plus advantages such as expert processing assistance.

IntElect. El-Exis SP. Systec

Machine Solutions for your Requirements

Sumitomo is one of the largest manufacturers of electrical injection molding machines globally, you have a competent and reliable partner at your side.

With more than 65,000 electric injection machines worldwide, Sumitomo (SHI) Demag sets the standard for efficient and precise industrial plastic processing.

As a global expert in the injection molding industry with many years of experience, Sumitomo (SHI) Demag is represented on all continents and provides you with a complete sales and service network.

| IntElect - highly precise | El-Exis SP - incredibly fast |

|

|

| An all-electric injection molding machine characterized by its high precision and energy efficiency. Low operating costs are what makes IntElect particularly efficient. The machine was built based on Sumitomo’s unique know-how in the development of all-electric drive systems. | With extremely short cycle times and the shortest injection times El-Exis SP is the ideal machine for the application in the high end packaging production. The machine convinces with its robustness and extreme filling dynamics. |

| Systec Sp - highly dynamic | Systec - highly flexible |

|

|

| Systec SP is equipped with a hybrid drive system and is particularly suited for applications in packaging production. Short cycle times and high availability provide the ideal solution for many quick applications. The Syste SP stands for production efficient processes and maximum cost effectiveness with best results. | The Systec is a hydraulic injection molding machine with a hybrid drive concept. It is designed to be extremely energy efficient and can be flexibly adjusted to many requirements and production processes – with possibilities ranging from the well-equipped basic model to the individually configured production cell. |

SE-EV-A Series Advanced All-Electrics

SE-EV-A Advanced All-Electric Injection Molding Machines

Providing the highest levels of precision, energy efficiency and molding stability, this new series advances zero-defect molding capabilities with machine setup and performance optimization that takes full advantage of the latest Z-Molding system and NC-10 Control.

Providing the highest levels of precision, energy efficiency and molding stability, this new series advances zero-defect molding capabilities with machine setup and performance optimization that takes full advantage of the latest Z-Molding system and NC-10 Control.

The SE-EV-A Series combines numerous exclusive technologies that can only be found on Sumitomo Demag all-electric injection molding machines.

- A new technology called S-MOVE replaces multi-step mold open/close speed settings with an algorithm-optimized speed pattern that is faster and smoother (less vibration). This, combined with the SE-EV-A’s fast clamp open/close speeds up to 47.24 in/s (1200 mm/s), cA new technology called S-MOVE replaces multi-step mold open/close speed settings with an algorithm-optimized speed pattern that is faster and smoother (less vibration). This, combined with the SEEV-A’s fast clamp open/close speeds up to 47.24 in/s (1200 mm/s), can significantly shorten cycle times.

- Z-Molding’s Flow Front Control (FFC) system, now with selectable Auto Setting, achieves complete and balanced filling with reduced injection pressure. FFC takes advantage of the energy in the flow front of the resin to complete filling in an even fashion as opposed to forcing material into open areas and thus flashing the areas that were already filled.

- Z-Molding’s Minimum Clamping Molding (MCM) system reduces clamp force requirements and ensures optimized venting of gases and flash-free molding. MCM allows the machine to automatically detect the minimum point at which the mold halves are completely parallel (mold touch) and defines the threshold where flash-free molding can occur and the optimum point at which the best cavity venting occurs.

- Z-Molding’s Simple Process Setting (SPS) system provides fast, guided setup, ease of use and machine optimization.an significantly shorten cycle times.

SE-EV-A advanced all-electric injection molding machines are available in five model sizes from 56 to 202 U.S. tons (500 to 1800 kN) (View Brochure)

SE50EV-A — 56 US tons, injection weight (GPPS) range 0.7-2.8 oz (19-80 grams)

SE75EV-A — 84 US tons, injection weight (GPPS) range 1.3-4.8 oz (38-137 grams)

SE100EV-A — 112 US tons, injection weight (GPPS) range 1.3-6.8 oz (38-193 grams)

SE130EV-A — 146 US tons, injection weight (GPPS) range 1.7-8.6 oz (49-244 grams)

SE180EV-A — 202 US tons, injection weight (GPPS) range 2.9-10.7 oz (83-302 grams >

New SE-EV-A HD Series

Mid-Sized All-Electric Machine, 247 to 562 U.S. Tons

This series combines significantly increased specifications with advanced technologies resulting in a substantially different mid-sized machine series that:

technologies resulting in a substantially different mid-sized machine series that:

- Brings the precision, productivity and profitability benefits of all-electric injection molding machine technology to applications with larger, heavier and more complex molds

- Efficiently handles higher injection requirements that would typically have been run on a hybrid or hydraulic machine

- Allows bigger parts to run on smaller machines

- “Meets or beats” specifications of other competitors’ next model size up all-electrics

What makes the SE-EV-A-HD different from other mid-size machines is the unique combination of robust, best-in-class specifications with exclusive technologies that reduce injection and clamp force requirements. This combination is key to the SE-EV-A-HD’s capability to compete with other manufacturers’ next model size up machines and to handle larger parts and molds with ease. (View Brochure)

Available in 8 models: SE220EV-A-HD, SE250EV-A-HD, SE280EV-A-HD, SE315EV-A-HD, SE350EV-A-HD, SE385EV-A-HD, SE450EV-A-HD and SE500EV-A-HD

All-Electric Injection Molding Machines

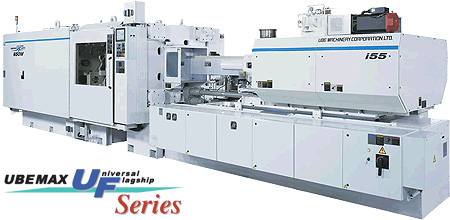

UBEMAX-UF Series - Clamping Force 650 to 3500 tons

User-friendly Controller Designed for Easy Operation: Equipped with e-HUMMA, this machine uses the newly developed Flex Servo Control to achieve steady precision injection control. The versatile, all-electric injection molding machine has evolved into a global standard.

MD Series - Clamping Force 650 - 3500 tons

Jointly developed by UBE Machinery and NIIGATA MACHINE TECHNO CO., LTD., the MD Series has consistently been the industry leader in developing large, all-electric injection molding machines since it appeared on the market in 1998 with the first 850-ton machine. The 1400-ton machine released in 2000, the 1800-ton machine released in 2002, and the 3000-ton machine released in 2006 all received excellent ratings (at the time, all machines boasted the largest clamping force in the world).

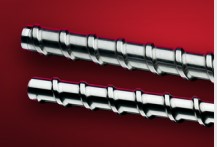

Zeiger Industries is the ultimate choice for high-performance plasticizing components:

|

MALLARD® Z4 VALVES - The Ultimate in Injection molding screw tips, Mallard® Z4 valves are the gold standard for solving the most demanding injection molding applications. Utilizing a "building block' design concept, Mallard® Z4 valves provide numerous advantages for any processing need, including: Numerous design & material selections, Replaceable wear components, Tough, reusable stainless steel retainer, Self-cleaning full-flow design, 2-Year wear-through guarantee on carbide faced value option. All valve designs allow use of the same retainer and rear seat, and incorporate a replaceable front seat and check ring concept. That saves you money and allows for easy customization of your valve for any need. |

|

GENERAL PURPOSE (GP) TOOL STEEL SCREWS - Can be manufactured to any design and material specification. ZEIGER PERFORMANCE (ZPTM) SCREWS - Recommended for extreme processing conditions and designed to handle the toughest conditions with ease. ZPTM screws are highly effective for shear sensitive applications, or where better melt quality and/or color mixing is a concern. Zeiger screw materials include, but are not limited to the following steels which include our proprietary ZROC, ZHCW 20 and ZSAR offerings as well as: CPM® S90V/420V, CPM® 9V, AISI D-2/DIN 1.2379, Inconel 625, Hastelloy C276. |

|

END CAPS FOR EVERY MAKE AND MACHINE MODEL

|

|

BEST-IN-CLASS THERMOSET MOLDING COMPONENTS

|

|

INJECTION MOLDING NOZZLES & TIPS

|

Give your local Barry Sales representative a call to learn more about how Zeiger Industries can help to optimize your operations.

![]()