Connectivity Solutions

Leuze - I/O-Link Master and Hubs: The MD7 System

I/O Modules with I/O-Link Interface for a Wide-Range of Automation Tasks

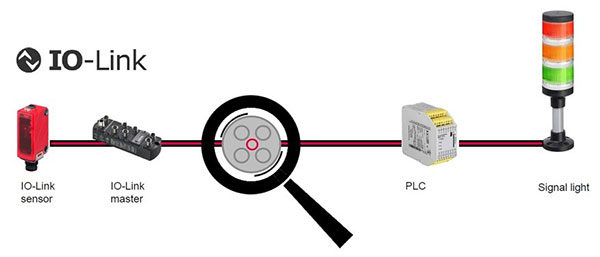

At the core of adaptable, transparent, and powerful automation lies the MD7 system from Leuze. IO-Link sensors transmit not only process data, but also device information, diagnostic data, and event messages. Leuze's Ethernet-based I/O modules with IO-Link technology combine the data and connect the individual machine modules to the control and superior systems. This makes the machinery modular. The IO-Link masters, which work with a variety of protocols, enable sensors and actuators to be flexibly integrated into existing infrastructures with different fieldbus and control systems. Process and device information is reliably transmitted from the individual IO-Link devices to superior management systems or cloud applications. Leuze's IO-Link modules and any other connected sensors and actuators are centrally commissioned, parameterized, and diagnosed via a web browser. IO-Link hubs can be used to expand the system economically and as needed.

Advantages

- Flexible integration in control and cloud - Flexible planning and reduced stocking costs: With PROFINET, Ethernet/IP*, and Modbus TCP, the IO-Link masters from Leuze support various protocols in a single device. Models with OPC UA are also available.

- Reduced installation effort - Low wiring effort and short installation times: The L-coded M12 Power connector delivers more performance in a single cable. This enables longer module chains and fewer cables and power supply units within the machine.

- High transparency - Easy access to diagnosis and configuration: The IO-Link master of the MD7 system comes with an integrated web server that enables remote parameterization and central monitoring of the connected sensors and actuators.

- Integrated system - Save costs with predictive maintenance and straightforward retrofitting: IO-Link enables the transmission of the diagnostic data needed to plan maintenance activities. If a sensor is replaced, the master automatically uploads the parameterization to the new device.

Leuze - Smart Core and Automotive Cable

The Intelligent Sensor Cable with Smart Core Technology

Leuze electronic presents a concrete innovation towards powering Industry 4.0 applications with its new Smart Core cable. With the smart factory revolution on the horizon, the Smart Core cable enables an innovative predictive maintenance measure specifically for applications with moving cables (i.e handling robots, welding robots, moving cables).

The cable contains an additional, special sacrificial wire that fails at approximately 80% of the cable’s lifecycle. The sacrificial wire is bridged with the supply voltage, and when the core breaks it gives an early warning of the impending end of the cable’s service life. Not only does this help to prevent unplanned downtime, but it increases system availability by predicting downtime and allowing for scheduled maintenance. With the future of smart automation already here, Leuze electronic presents a smart solution to a critical but often overlooked component of an application.

For more information on the Smart Core Cable or other Leuze connectivity offerings please contact your local Barry Sales Engineering Representative.

Mencom - Junction Blocks

The industrial automation world is constantly searching for ways to increase installation reliability, speed up the installation process, and reduce downtime. Junction blocks often referred as terminal blocks and distribution blocks provide a simple and effective way through consolidating connections from various types of control systems and sensors that have many I/O points.

Mencom Junction Blocks offer a wide range of circuit configurations in 7/8-16 MINI series, M12 & ½-20 Micro series, M8 Nano series, and DeviceNet Series. They feature a homerun connector (cable, cable with connector, receptacle, or field wireable) which easily routes signals from multiple inputs back to the main control system. This significantly reduces potential errors associated with wiring, rewiring and I/O replacement. Furthermore, both cost and downtime are also minimized.

Mencom - Space-saving Right Angle Solution for High-Power Applications

Meet the New, MIXO High Current Module for crimp cable lugs connection.

In order to cope with the fast-growing energy transition market demanding flexible high-power capabilities, the integration of power systems and associated cable assemblies must be secure, cost-effective, and space-saving. However, high-power modules in the current range between 70A and 200A have conductors with large wire-cross sections, even up to 70mm2. These wires are often challenging to handle because the thickness reduces the bending radius and requires adequate floor space.

high-power capabilities, the integration of power systems and associated cable assemblies must be secure, cost-effective, and space-saving. However, high-power modules in the current range between 70A and 200A have conductors with large wire-cross sections, even up to 70mm2. These wires are often challenging to handle because the thickness reduces the bending radius and requires adequate floor space.

The new MIXO right-angled high-current modules (CX-01YA) are designed to minimize space installation requirements with a compact 90° connection that removes bending of large diameter wires (up to 70mm2) and ensures reliable 200A rating performance. The main feature of this new module is the special insulating cover plate that can not only prevent accidental contact between cable lugs on adjacent modules but also save the nominal voltage rating of 1000V planned for the 200A modules while connecting the DIN 46235 pre-insulated crimp cable lugs.

These 200A right-angled modules with the screw termination are compatible with the standard bulkhead mounting housings. They also can be used to extend a busbar connection or to power control cabinets, HVAC systems, and batteries for energy storage backup applications.

Mencom - High Temperature Series Enclosures & Inserts

Rectangular Connectors with the Heat Shield for High-Temperature Manufacturing Environments

In some harsh manufacturing industries, electrical connectors are required to ensure reliable operation in high-temperature environments. Without proper equipment and protection, those connectors exposed to high temperatures can easily fail and can cause serious operational problems. Therefore, the use of special electrical connectors and enclosures developed for high-temperature environments will extend the life of industrial applications on the harsh manufacturing floor.

The operational temperature of the Mencom standard metal rectangular connectors is between -40°C and 125°C. However, the Mencom high-temp series enclosures and inserts are designed to withstand a higher range of temperatures up to 180°C (356°F) and cold temperatures down to -40°C (-40°F) when they are installed together. The enclosures are made of die-cast aluminum coated with high-temperature resistant, red-colored thermosetting powder. In addition, their flange and sealing gaskets are made of anti-aging heat-resistant fluoroelastomer for added protection against heat. The high-temp inserts are made of self-extinguishing thermoplastic material and are color-coded dark brown.

The sizes of the high-temp series connectors are available in “21.21”, “44.27”, “57.27”, “77.27”, “104.27”, and “104.62”. According to EN IEC 60529, the size 21.21 enclosure provides IP44 rating and the other sizes IP65 rating.

For more information on Mencom's full-range of High-Temperature Enclosures and Inserts, please give us a call at 636-326-1211.

Mencom - Armored Cordsets

Connectivity Solutions for Harsh, Rugged, Environments

One of the biggest challenges manufacturers struggle with today, is how to prevent downtime or outages caused by connection failure. In most cases downtime is caused by one of the following conditions:

- Physical failure by repetitive impacts and abrasion

- Damage by high pressure washdown and cleaning chemical

- Damage by extreme temperature

- Weld Slag

With the new line of Mencom’s armored, quick disconnect cables we can provide a rugged solution for harsh environments. Available in 7/8” Mini, M12 Micro-DC & M12 Ethernet D-Code, ½” Micro AC and M8 Pico Connectors.

Chemicals, Abrasions, High Temperature, Water, Pressure, Welding, Cutting, Marine applications, and beyond create some of the harshest environments for cables. When you are faced with the extreme, but still need the convenience of plug and play connectivity – look no further! We can provide the solution for those problem environments to keep your equipment running longer, in turn saving you on costly down time.