Inspekto Joins the Fight Against Covid-19

During the Covid-19 pandemic, a German manufacturer installed the INSPEKTO S70 to inspect FFP2 face masks, which are CE-certified and conform with the PSA regulation EU2016/425. There are already multiple lines in operation, producing 30 masks per minute — a figure that is expected to double.

The masks are classified as medical PPE and are supplied to hospitals and other professional bodies, so it's classed as a medical device, meaning there is zero tolerance for failures or defects.

The areas inspected by the INSPEKTO S70, per the customer requirements are:

- Correct placement of the nose bridge

- Ultrasonic welding of the fleece and filter layers

- The existence and quality of the printed text

- Welding of the masks’ straps

Failures in the nose bridge could cause irreparable damage to the cutting machine, which is part of the line. Therefore, the nose bridge was defined as a critical inspection area, requiring critical detection reporting if a defect occurred. The

INSPEKTO S70 is integrated with the line's PLC to report the inspection decision and enable the removal of the defected masks.

Why INSPEKTO?

- The immediacy in which the INSPEKTO S70 was ready for commercial deployment, due to the fact it is an out-of-the-box product without the need for system integration

- The quick resolution for new unforeseen needs requested by the customer

- The ability of the INSPEKTO S70 to overcome the challenges of the dynamic production environment, such as lights changes and vibrations

- The simplicity of installation and maintenance, which the end user can carry out without prior machine vision expertise

- The same electro-optic system supports multiple different use cases with no programming. A universal product was a huge advantage as different types of masks will be produced on the same line

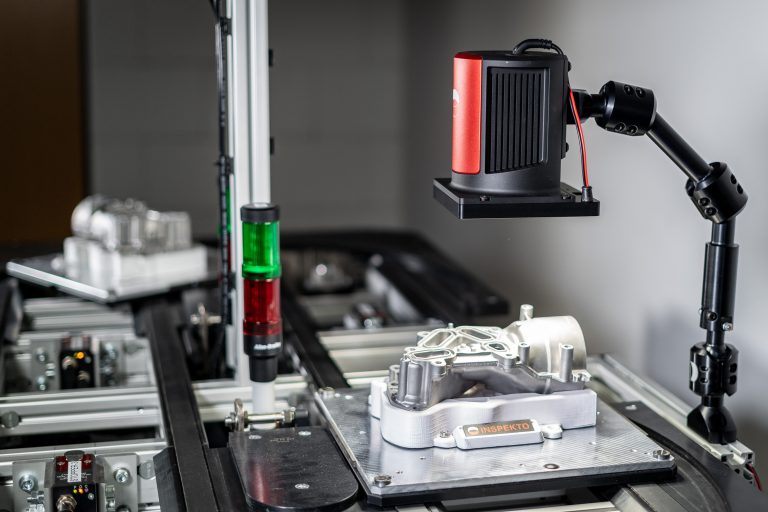

About the INSPEKTO S70

The INSPEKTO S70 enables manufactures to gain high production flexibility without sacrificing the quality of their production. The system can be deployed in-line or at the end-of-the-line, and this, coupled with its high affordability unlocks the potential of mass-deployment industrial inspection. Simplifying the integration to the production line due to the INSPEKTO S70’s unique auto-triggering capability, still the system can connect to the line’s PLC using all common protocols such as PROFINET, Ethernet/IP, Digital I/O and more.

This is just one application that was no match for the INSPEKTO S70! If you have a quality challenge that you need help solving, give your Barry Sales Representative a call today at 636.326.1211.