Mold & Tooling

Now Representing - Pascal a Premier Magnet Clamp Maker

Magnetic Clamps

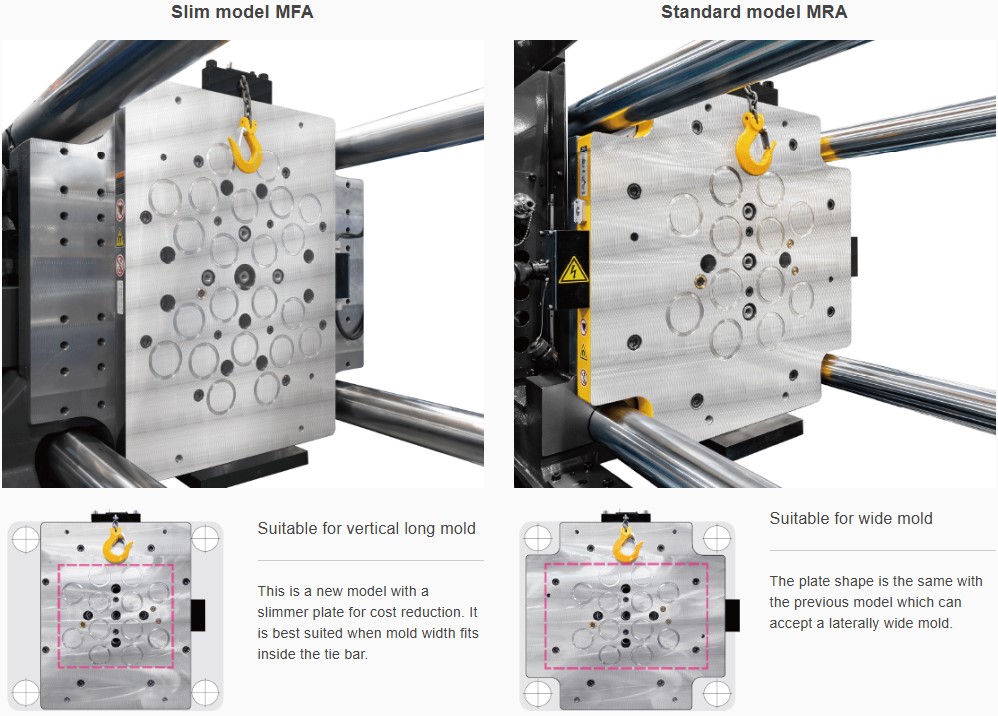

Circle Core Mag Clamp MFA / MRA - Plate thickness=50mm, Operating Temperature=120℃ - Supports Vertical and Horizontal loading. Pascal offers 2 models in accordance with the size and shape of the user's mold.

Features

- Easy die change

- Mold displacement detection system

- No need to unify the mold sizes

- Use the machine platen area to the maximum

Pascal Mag Clamp MGA / MGB - Plate thickness=35mm/50mm, Operating Temperature=150℃ / 180℃ - Ideal for Vertical and Multi-Color Machines

Features

- Easy die change

- Mold misalignment detection system

- Mold size unification not necessary

- Maximizes the mold's machining surface

Hydraulic Clamps / Air Clamps

Hydraulic Clamps

Air Clamps

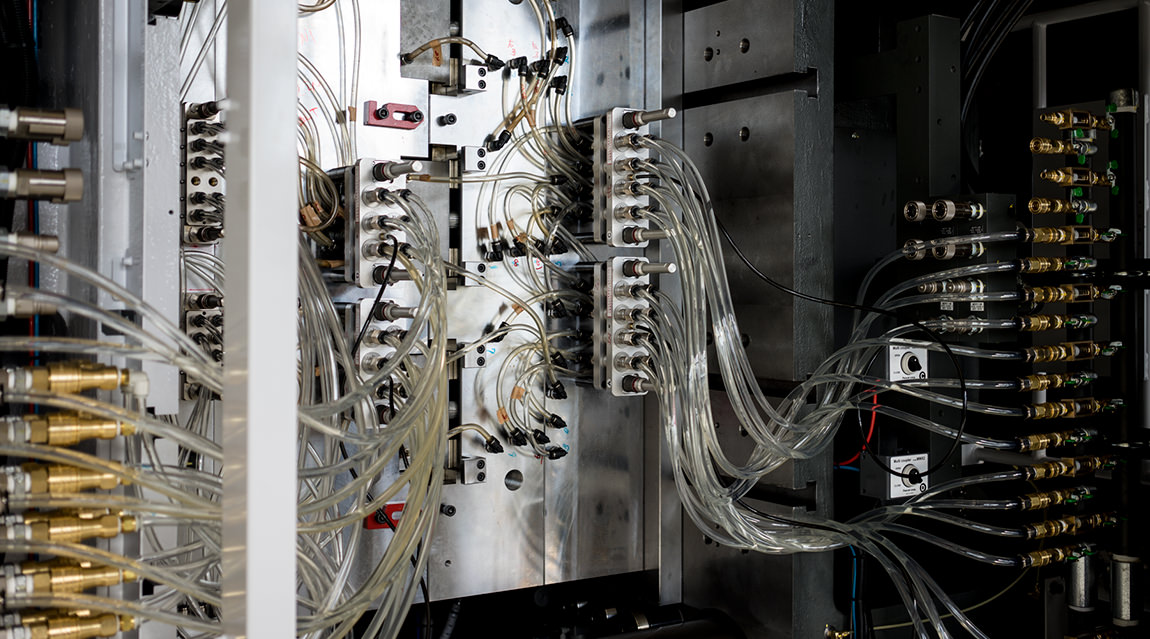

Multi Coupler (Manual)

Multiple couplers are connectable easily and securely by pushing the gripper slightly. Fluied | Hydraulic, Water, Air. Number of ports: 4,6,8, or 12

|

|

Model MCA - Open (Check valve-less) model

Model MCC - Check valve model

For information regarding the Pascal products featured above, please give your local Barry Sales represenative.

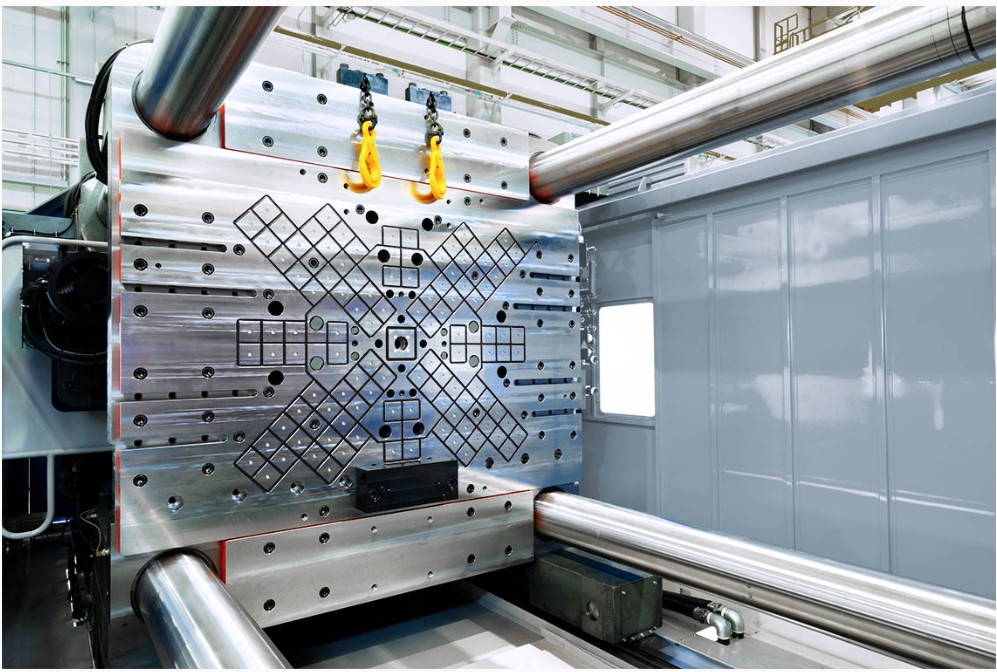

Kosmek - Magnetic Clamping Systems

Reduce Mold Change Time & Increase Mold Change Safety

Invisible magnetic forces are digitally visualized. MIMS Multi Information Monitoring System shows magnetic forces with a digital display. It is also able to measure plate surface temperature and calculate the change of magnetic forces caused by temperature changes. Since every magnet core is equipped with individual magnetic force sensors, it measures the area that the mold is in contact with the plate, enabling to confirm accurate magnetic force even when there are through holds on the mold.

System shows magnetic forces with a digital display. It is also able to measure plate surface temperature and calculate the change of magnetic forces caused by temperature changes. Since every magnet core is equipped with individual magnetic force sensors, it measures the area that the mold is in contact with the plate, enabling to confirm accurate magnetic force even when there are through holds on the mold.

Kosmek - New Hydraulic Clamps - G Series

GBB Clamp - is manually slid in the T-slot and locks the mold. Suitable for Non-Standardized Mold Widths. Single Hydraulic Circuit with Basic and Simple Circuit Structure.

GBC Clamp - is manually slid in the T-slot and locks the mold. Suitable for Non- Standardized Mold Widths. Single Hydraulic Circuit with Basic and Simple Circuit Structure. Longer stroke allows for variation in mold clamping thicknesses.

Standardized Mold Widths. Single Hydraulic Circuit with Basic and Simple Circuit Structure. Longer stroke allows for variation in mold clamping thicknesses.

GBE Clamp - with an air cylinder that slides in the T-slot and locks the mold  automatically by remote control. Clamp movement is completely automated.

automatically by remote control. Clamp movement is completely automated.

GBF Clamp - with an air cylinder that slides in the T-slot and locks the mold  automatically by remote control. Clamp movement is completely automated.

automatically by remote control. Clamp movement is completely automated.

Longer stroke allows for variation in mold clamping thicknesses.

GBM Clamp - Block fixed clamp which does not require T-slot, and slides in the  block by hand. Suitable for Non-Standardized Mold Widths.

block by hand. Suitable for Non-Standardized Mold Widths.

GBR Clamp - Block fixed clamp which does not require T-slot, and slides in the  block automatically with an air cylinder. Suitable for Non-Standardized Mold Widths.

block automatically with an air cylinder. Suitable for Non-Standardized Mold Widths.

![]()

Leading Supplier of Temperature and Sequential Valve Gate Control Systems

Product Lines Include:

LEC - affordable, full-featured control for up to 24 zones of temperature control

G24 - for 18 to 480 zones of temperature control - the next generation in temperature control from Gammaflux, featuring the following benefits:

|

|

TTC - advanced, powerful, highly technical control for integrated temperature or stand-alone sequential valve gate control (SVGC) applications, up to 640 zones; panel mount options for injection molding machine also available.

Plastics Processing, Mold Maintenance and Mold Making Solutions.

For over 58 years, Slide Products has been supplying the Plastics and Food

Industries, as well as the Tool and Die shops with Mold Release, Lubricants, Cleaners, Purge compounds, Rust Preventives, cutting oils and more, all formulated to help you economically maximize your productivity. Barry Sales Engineering is a local stocking distributor, we can review your applications, recommend a product and send/bring you samples to try out. Please download the SLIDE catalog for all of products they offer and let us know how we can help.

Build your own SLIDE Sample Kit

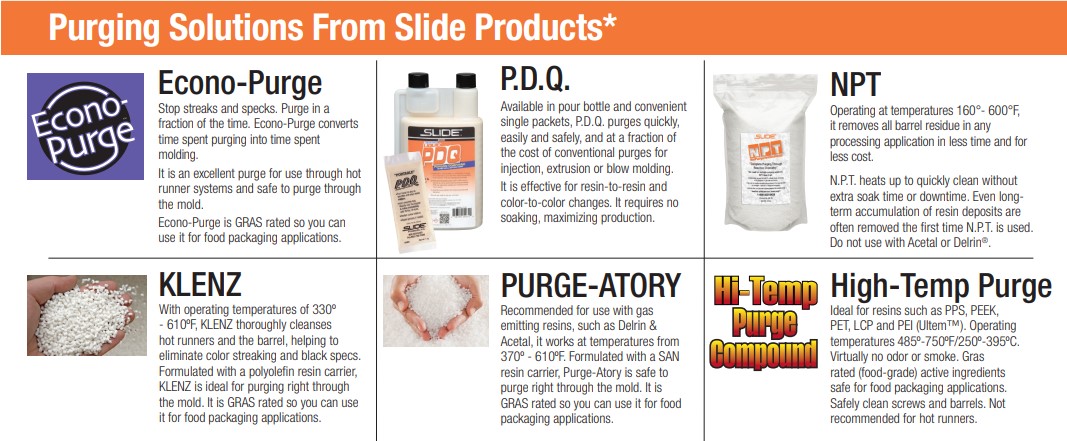

Purging Compounds from Slide Products Stop Specks & Streaking

If you’re running pounds of resin through the barrel and mold until it comes out clean, this wasteful process will cost you time and create decreased profit margins. The right purging compound will turn much of that unwelcome expense back into output. Slide’s purging compounds speed up resin-to-resin and color-to-color changes, maximizing your productivity and decreasing the costs.

Offering full-line of Mold Maintenance Products, Mold Release, Cleaners, Degreasers, Lubricants and Rust Inhibitors

Barry Sales Engineering proudly represents the DAC product line offering, please give your local Barry Sales Engineering representative a call for current pricing and lead-times.