Cooling & Heating Systems

Announcing the New Mini-Aquatherm RMC Series

The Mini-Aquatherm is similar to the Aquatherm but almost half the size.

Mini-Aquatherm RMC Series mold temperature controllers provide the best available components such as cast pump volute/heater tube/mixing assemblies, high flow pumps with leak-resistant silicon carbide seals and rugged Incoloy sheathed heaters for years of maintenance free operation. Each injection molding temperature control system comes with a large, user-friendly operator interface that provides a wide array of operational and diagnostic information.

components such as cast pump volute/heater tube/mixing assemblies, high flow pumps with leak-resistant silicon carbide seals and rugged Incoloy sheathed heaters for years of maintenance free operation. Each injection molding temperature control system comes with a large, user-friendly operator interface that provides a wide array of operational and diagnostic information.

Available in 2 models (Premium & Standard); designed for a better level of control and data.

RMC Family Overview

| 1/3 & 1/2 HP (.25 & .37 KW) | Intelligent vent control - at start-up the automatic vent sequence deactivates when the mold circuit is above 120°F to avoid cooling of the mold after temporary power interruptions |

| 3 KW and 6 KW heat range | Adjustable deviation alarm time delays |

| High flow pumps | Supply and return temperature displays |

| Leak-resistant, silicon carbide severe-duty pump seal | Solid top protects motor from dirt or fluid contamination |

| Long-life, low watt density Incoloy heaters resist corrosion better than copper or stainless steel | Four swivel casters for easy movement |

| Heavy-duty cast-iron pumps, heater tubes, and mixing tubes with O-ring seals reduce threaded fittings that can cause internal pressure losses and are prone to leaks | Lifetime pump/heater casting warranty |

| 24 VDC control circuit power | Lifetime pump seal warranty |

| Tilted front panel angled for optimal viewing | 3-year parts, 3 years labor |

For more detailed information on the RMC Mini-Aquatherm models and their additional features, please give your Barry Sales representative a call at 636.326.1211.

Thermal Care's Hot Oil Temperature Controller

Oiltherm ROH Series

Oiltherm ROH Series hot oil temperature control units are designed to work with a wide range of high temperature applications in the 125°F to 575°F (52°C to 302°C) range. The Oiltherm assures high velocity oil flow across heater elements for optimum heat transfer and fluid life. The oil is preheated to reduce viscosity before allowing the pump to run. A PLC controller allows customized settings for daily start/stop times and a temperature deviations alarm and a password lockout protects temperature set point.

Overview

| 12 KW to 96 KW | Oil level safety prevents operation under low oil conditions |

| Magnetic driven pump without wear-able mechanical seals | Stainless steel reservoirs |

| 3.5" touchscreen controller | Stainless steel heat exchanger connections for corrosion free operation |

| Up to 8 ramp programming "recipes" with up to 8 steps each for heating and cooling scheduling | High temperature safety at 660°F (349°C) |

| Supports various interfaces, including TTY, Ethernet IP, and Profibus | Dual reservoir system includes operating and expansion reservoirs |

| Automatic oil preheat to 100°F (38°C) | Complete insulation of oil circuit and operating reservoir maintains temperature and saves energy |

| Low watt density stainless steel heater elements provide long life and built-in standby | Premium quality solenoid valve assures precise temperatures |

| Heat shield and control cabinet fan cooling protects hot oil temperature control systems and pumps | Easy access cabinet with removeable top/side panel |

| Convenient oil fill location allows oil to be added without removing cabinet | Four swivel casters make unit easy to move |

Available Options

|

|

Thermal Care - RQT Mold Temperature Control Units

Available in 3 models; designed for a better level of control and data.

Accurate, dependable and easy-to-use

When you need a compact water temperature control unit for your application, you can count on Thermal Care. We understand how to meet your temperature control equipment needs.

Aquatherm RQT Series temperature controllers provide the best available components such as cast pump volute/heater tube/mixing assemblies, high flow pumps with leak-resistant silicon carbide seals and rugged Incoloy sheathed heaters for years of maintenance free operation. Each control system comes with a large, user-friendly operator interface that provides a wide array of operational and diagnostic information.

The Thermal Care Temperature Controller Family - Offers a suite of powerful and efficient mold temperature controllers. Each unit is reliable, easy to operate, and built for dependable operation using an assortment of quality components.

For more information and available options, give your Barry Sales Representative a call today at 636.326.1211.

Thermal Care's Accuchiller KSE Series Packaged Outdoor Chiller offers:

Dual refrigeration circuit, 40 to 60 Ton

Dual fluid & refrigeration circuit, 80 to 120 ton

KSE Series industrial outdoor air-cooled chillers feature a compact, all-in-one  package designed to minimize installation cost, maximize usable space and lower electric bills. Designed for harsh outdoor environments KSE Series chillers require no options to operate within the standard -20°F to 125°F ambient environment conditions. Standard process fluid temperatures of 20°F to 80°F are ideal for industrial applications. The modular design allows up to 12 refrigeration circuits to be combined into a single system for up to 720 tons of cooling capacity.

package designed to minimize installation cost, maximize usable space and lower electric bills. Designed for harsh outdoor environments KSE Series chillers require no options to operate within the standard -20°F to 125°F ambient environment conditions. Standard process fluid temperatures of 20°F to 80°F are ideal for industrial applications. The modular design allows up to 12 refrigeration circuits to be combined into a single system for up to 720 tons of cooling capacity.

Chillers are available with or without integrated pumping packages, including high and low pressure pumping with dedicated stand-by and built-in pressurized and non-pressured tanks.

and low pressure pumping with dedicated stand-by and built-in pressurized and non-pressured tanks.

KSE Series chillers come standard with Dynamic Lift technology to continuously calculate the lowest allowable refrigerant pressure for any combination of operating conditions for maximize chiller energy savings and stable process fluid temperatures of +/- 1°F.

Features

- Wide operating conditions

- Ambient Environment: -20°F to 125°F

- Process Fluid Circuit: 20°F to 80°F

- Integral air-cooled rugged microchannel condenser for class-leading efficiency

- Innovative PLC Control System with a large high-resolution color touch-screen operator interface and an extensive list of operational information including remote monitoring

- Direct drive scroll compressors for low maintenance and energy efficiency

- Compressor staging for capacity control with optional hot gas bypass for even greater unloading capabilities

- Compressor anti-cycle and start-up timer

- Lead/lag compressor staging to alternate primary compressor

- Brazed plate evaporators maximize performance and increase resistance to costly freeze-up failures

- Standard variable-speed drive fans reduce energy usage and provide optimum part-load performance for industry-leading IPLV, all while reducing noise levels for sound-sensitive environments

- C-UL 508A listed and labeled control panel

- In-line evaporator strainers assure full evaporator performance

- Single point connection for electric hookup at control cabinet

- Electronic expansion valves

- Liquid line solenoid valves to extend compressor life

- Refrigerant sight glasses

- Liquid line filter driers with removable cores

- High and low refrigerant pressure switches

- Alarm horn with silence button

- 3-phase power monitoring and safety protection

- Environmentally balanced 410a refrigerant

For more information and available options, give your Barry Sales Representative a call today at 636.326.1211.

Thermal Care's Portable Accuchiller Family

EQ (1 to 3 ton), NQ (4 to 40 tons), NQV (5 to 20 tons)

Providing a suite of efficient, reliable, and high-quality industrial packaged chillers. The Accuchiller combines a refrigeration chiller and pumping system in a portable industrial-grade cabinet.

EQ Series Portable Chillers feature a compact footprint with an easily accessible interior  and a microprocessor that provides precise temperature control and extensive diagnostics. Air-cooled, water-cooled and remote condenser models are packed with many standard innovative features that improve chiller performance and reliability.

and a microprocessor that provides precise temperature control and extensive diagnostics. Air-cooled, water-cooled and remote condenser models are packed with many standard innovative features that improve chiller performance and reliability.

NQ Series Portable Chillers use components such as R410A  refrigerant, scroll compressors, micro-channel condensers, low noise fans, stainless steel brazed plate evaporators, and sophisticated controls provide the best available technologies for the ultimate performance and reliability in a chiller package.

refrigerant, scroll compressors, micro-channel condensers, low noise fans, stainless steel brazed plate evaporators, and sophisticated controls provide the best available technologies for the ultimate performance and reliability in a chiller package.

NQV Variable Speed Chillers have the same great features as the NQ Series, but with the addition of an optional variable speed compressor for significant energy savings. Available on 5, 10, 15, and 20 ton NQ Series. This conventional portable chiller uses a compressor running at a continuous speed, also known as a fixed speed compressor. Regardless of the requirements placed on it by the process load, the compressor speed remains at 100%. Fixed speed chillers employ a “hot gas bypass” to maintain the demand on the compressor to avoid wide fluctuations in the coolant temperature delivered to the process for consistent output.

conventional portable chiller uses a compressor running at a continuous speed, also known as a fixed speed compressor. Regardless of the requirements placed on it by the process load, the compressor speed remains at 100%. Fixed speed chillers employ a “hot gas bypass” to maintain the demand on the compressor to avoid wide fluctuations in the coolant temperature delivered to the process for consistent output.

NQV Variable Speed Chillers with advanced PLCs are at the technological forefront of the process cooling industry. The controller constantly monitors the heat load and adjusts the compressor speed for peak efficiency and temperature control and eliminates the need for hot gas bypass. By automatically adjusting the compressor speed, the chiller works only as hard as necessary to provide optimum performance with significantly reduced power use. Studies have shown that a 20% reduction in motor speed can lead to a 51% energy savings.

Thermal Care's TCF Series Central Chiller

Single Circuit Chiller 100 tons

Thermal Care offers the new TCF Central Chiller which combines the efficiencies of  both a hybrid file evaporator and a Turbocor variable speed centrifugal compressor to deliver optimum full and part load efficiencies. The result is one of the most energy efficient central chillers ever build.

both a hybrid file evaporator and a Turbocor variable speed centrifugal compressor to deliver optimum full and part load efficiencies. The result is one of the most energy efficient central chillers ever build.

Features

- Water cooled single circuit model

- Advanced PLC System maintains stable and reliable operation of the chiller

- Hybrid film evaporator for the most efficient heat transfer

- Direct-drive variable-speed Turbocor centrifugal compressor technology continuously adjusts speed to match load and reduce operating costs

- C-UL 508A listed and labeled industrial control panel

- Rotary circuit breaker for compressor

- Single point connection for electrical hookup at control cabinet

- Only one major moving part - the compressor impeller which is used to compress gas and provides the highest full load efficiency and less energy use.

- Modular expansion to over 600 tons using up to six chillers.

- TC Series Chillers come standard with Dynamic Lift technology

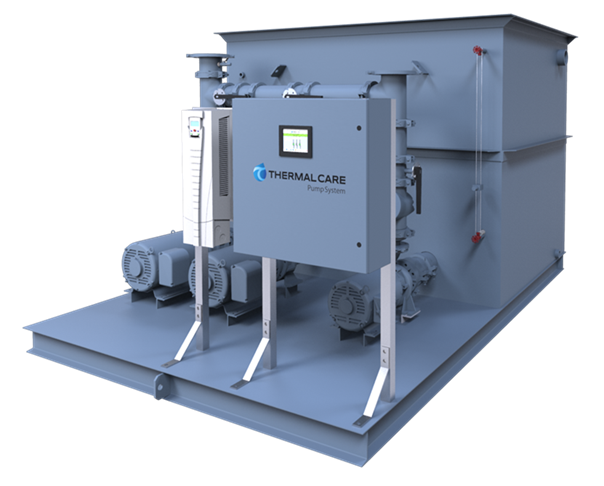

Thermal Care's Pump Tank Systems

Tank Systems for Cooling Tower and Central Chiller Applications

Thermal Care offers a complete line of pre-engineered tank systems for cooling  tower and central chiller applications with the highest quality design and construction features available. Standard, full sized pump trim, extended pump suctions legs, welded seams and solid steel decking under pumps and a PLC are just some of the value-added features incorporated into every system.

tower and central chiller applications with the highest quality design and construction features available. Standard, full sized pump trim, extended pump suctions legs, welded seams and solid steel decking under pumps and a PLC are just some of the value-added features incorporated into every system.

Features

- Available in fiberglass or stainless steel for indoor or outdoor installations

- PLC for quick and easy operation

- Premium-efficiency, close-coupled, non-overloading, centrifigual pumps provide optimum flow and pressure with reduced electrical costs

- All pumps are mounted on a solid deck for added rigidity, serviceability, and safety

- Grooved pipe connecting system reduces the need for flexible couplings and eliminates pipe stress at start-up; connections readily disassemble for fast maintenance and reconfiguration when adding or changing pumps

- Full size pump suction legs on stainless steel tanks feature a 45° angle opening to prevent vortexing and pump cavitation, which can lead to pump damage and reduced pump performance

- Liquid filled pump discharge pressure gauges enable accurate flow adjustment; isolation cocks prevent gauge pressure fluctuation and extend pressure gauge life

- Factory mounted thermometer allows quick monitoring of process water temperature

- Discharge check valve stops supply line flowback, eliminates the potential for water hammer at pump start-up

- Properly sized pump suction and discharge piping trim eliminates excessive pressure drop and maximizes flow to process

- Prewired and mounted control panel is hardwired to pump motors using weatherproof conduit, simplifying field installation and reducing installation costs (optional)

- Suction buttlerfly valve allows pump to be changed without draining the reservoir

- Automatic water make-up assembly maintains constant water level

- Low level alarm protects pumps and alerts operator to problems quickly

- External sight glass with shutoff valves

- Overflow and fill drain connections

For more information on the full line of Thermal Care's cooling solutions, please give your local Barry Sales Representative a call.

Self-Cleaning Water Filters

High-quality, high-performance self-cleaning water filters mean virtually no maintenance, virtually no worries!

Mold Temperature Regulator

The Smartflow Mold Temperature Regulator - Reduces condensation when used on a feed throat.

Drying plastic can be difficult in the summertime. Hygroscopic materials can soak up moisture from the air making drying difficult at best.

moisture from the air making drying difficult at best.

One way to combat this is to install a Smartflow Mold Temperature Regulator at the feed throat of your molding machine. Raise the feed throat temperature above the dew point to reduce moisture absorption that affects molded part quality.

- Replaces conventional mold heaters

- Low cost

- Holds temperature regardless of variables

- Unaffected by pressure changes

- Control different temperature zones with multiple units

- Unaffected by supply water temperature changes

- Low maintenance

- Uses no electricity

- No floor space required

Three models available:

- 1/4" NPT inlet and 1/2" NPT outlet

- 1/4" quick-connect socket inlet and 1/4" quick-connect plug outlet

- 3/8" quick-connect socket inlet and 3/8" quick-connect plug outlet

For more information on the Mold Temperature Regulator and how it can help in your process, please give your local Barry Sales Representative a call.

Water Manifolds

Increase cooling efficiency and speed cycles by providing ample water supply to cooling processes

Aluminum Manifolds 3/4" to 2" Supply

Features and Benefits

- 300°F/149°C Operating Temperature Rating for application flexibility

- 150psi Maximum Pressure Rating

- One-piece aluminum extrusion

- No seams

- Red and Blue Anodized for corrosion resistance and function identification (supply and return)

- Various port sizes and thread types available (NPT, BSP, SAE)

- Brass end plug included (NPT only)

- Pre-drilled mounting holes

- Unique dovetail lock feature for paired mounting on 3/4", 1", and 1-1/2" sizes

- Standard items in stock - custom items available

- Optional ball valves, flowmeters and regulators can be installed to suit specific applications

Stainless Steel Manifolds

Smartflow Stainless Steel Manifolds are made to last. Superior hand-welded  construction and high quality stainless steel components create a reliable product on which industry depends in demanding applications. Note: These manifolds are available in standard and custom sizes.

construction and high quality stainless steel components create a reliable product on which industry depends in demanding applications. Note: These manifolds are available in standard and custom sizes.

Features and Benefits

- 250°F/121°F Operating Temperature Rating for application flexibility

- Rated for 250 psi a\maximum liquid pressure to suit most installations

- Chemically compatible stainless steel construction

- Corrosion resistant

- 100% leak tested

- Brass end plug included (NPT only)

- Integral mounting brackets for stability

- Many sizes stocked for quick delivery

- Custom designs available

- Optional ball valves, flowmeters and regulators can be installed to suit specific applications

Duoflow Aluminum Manifolds are divided internally and color-coded red & blue to denote Supply and Return cooling in a compact arrangement. These manifolds have compressed port spacing and are designed for installation on injection molds in storage. By storing molds with water circuits pre-plumbed to the manifold, only one hookup for supply or return is needed. This is one of the Quick Mold Change techniques that save injection molders time and money.

Features and Benefits

- 3/4", 1", 1-1/2" and 2" inlet sizes (NPT or BSP)

- 1/4", 3/8" and 1/2" port sizes (NPT or SBP)

- Red & Blue Anodized to denote Supply and Return circuits

- Common sizes in stock

- Custom manifolds made to order

- Quick disconnect and hose barb fittings optional for convenience

For more information on the full line of Smartflow Manifolds and which would work best in your application, please give your local Barry Sales Representative a call.